The 2026 mobile computing landscape, dominated by powerful AI-ready CPUs and high-end GPUs (like the NVIDIA RTX 50-series and AMD Ryzen AI 9), has made thermal management not just an option, but a critical necessity. As laptop chassis continue to thin, heat density increases exponentially, leading to severe thermal throttling, reduced frame rates in gaming, and crippled performance in demanding tasks like MLOps and 3D rendering.

The traditional cooling pad—a simple plastic platform with noisy fans—is now obsolete. The Ultimate Laptop Cooling Pad of 2026 is a hybrid thermal solution, combining sophisticated airflow with advanced materials and even thermoelectric cooling to achieve a substantial, measurable drop in component temperature, thereby unlocking the laptop’s full potential. This comprehensive analysis evaluates the three most critical criteria: Performance (Temperature Delta), Noise Level, and Material Innovation.

1. Performance Benchmark: The True Temperature Differential (ΔT) Test

The true measure of a cooling pad is the temperature differential ($\Delta T$)—the difference between component temperatures (CPU/GPU) with and without the pad under maximum stress (e.g., Prime95 and FurMark simultaneous stress tests). In 2026, acceptable performance is defined by a consistent $\Delta T$ of 8°C or more.

The Role of Active Cooling Technology

The most effective modern cooling pads leverage technologies far beyond simple axial fans:

-

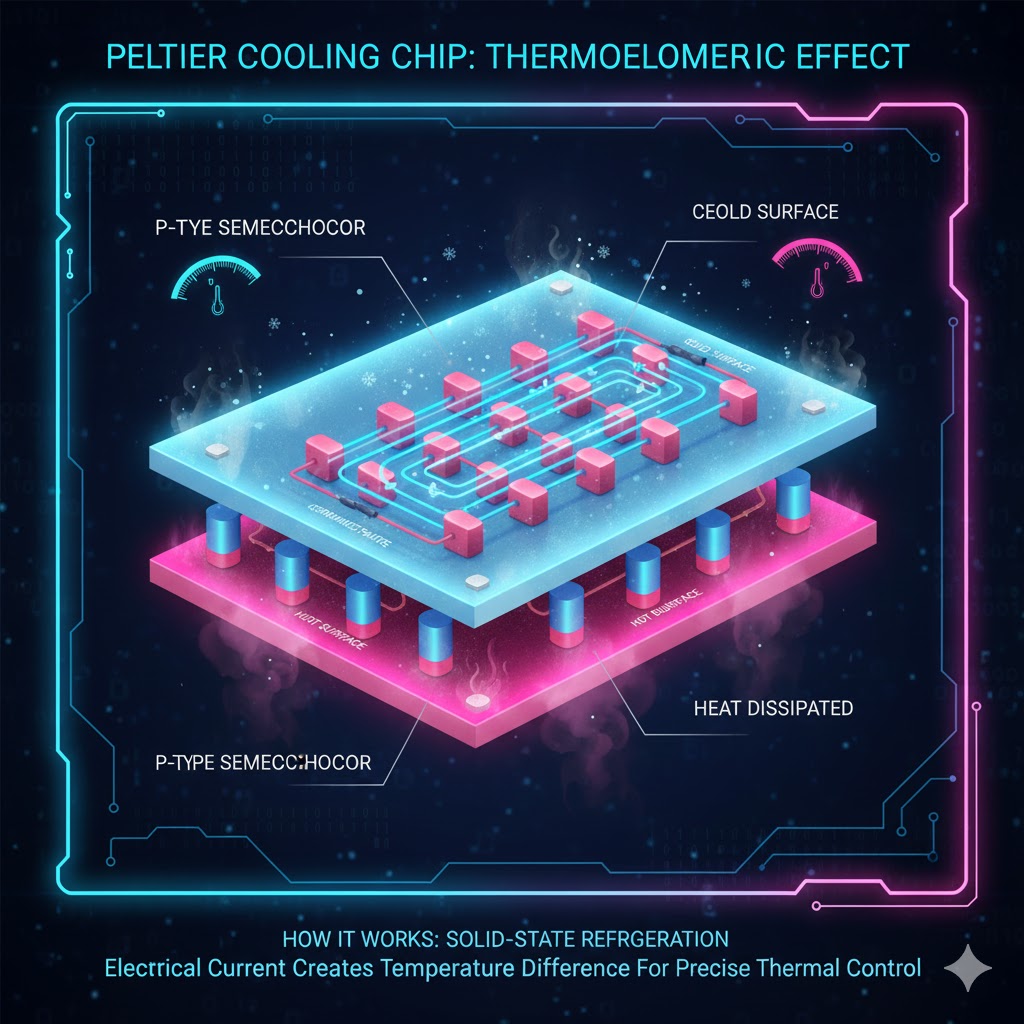

Peltier (Thermoelectric) Cooling: The cutting edge of heat management uses the Peltier effect, where passing an electrical current between two dissimilar conductors creates a temperature difference. The cold side directly contacts the laptop’s heat-generating areas, chilling the intake air below ambient temperature. This offers the highest potential $\Delta T$ (often exceeding 12°C). However, this technology demands high power draw and requires robust cooling on the hot side to prevent overheating the entire pad.

-

Vacuum (Blower) Sealed Designs: Pads featuring a sealed chamber design (e.g., IETS GT-series style) create a high-pressure, directed airflow. By using foam seals around the laptop’s intake vents, they force cool air directly into the machine, optimizing the internal cooling system’s efficiency and avoiding thermal bypass.

Key Performance Metrics (Beyond RPM)

Modern analysis requires looking beyond fan RPM:

-

Static Pressure (mmH₂O): This measures a fan’s ability to push air through restrictive vents and filters. High static pressure is crucial for tightly packed, high-performance laptops.

-

CFM (Cubic Feet per Minute): Measures the total volume of air moved. A high CFM combined with high static pressure defines the most powerful thermal engine.

For users engaged in high-demand tasks, like running deep learning models or extensive video rendering, pairing a high-performance laptop (e.g., the latest M5 MacBook Pro) with an advanced cooling solution is essential to prevent CPU clock speed degradation. Learn how thermal limitations impact professional workflows in our related analysis: M5 MacBook Pro 16-inch Review: Battery Life, Thermal Performance, and Creator Workflow

2. Noise & Acoustic Profile: The Decibel Challenge

Performance cannot come at the expense of comfort. The noise level is measured in decibels (dBA), and the industry standard for quiet operation in 2026 is sub-30 dBA at maximum fan speed, measured from a standard distance of 50cm.

Magnetic Levitation (MagLev) Fan Technology

The key to achieving high performance at low noise is the adoption of Magnetic Levitation (MagLev) Bearings.

-

Zero Frictional Noise: MagLev fans utilize magnetic forces to suspend the fan rotor, completely eliminating the mechanical friction noise produced by traditional ball bearings or sleeve bearings. This allows fans to spin faster (up to 2,400 RPM or more) while maintaining noise levels as low as 19–20 dBA, far quieter than the typical 25-30 dBA of older fans.

-

Extended Lifespan: The lack of physical contact significantly extends the fan’s Mean Time Between Failures (MTBF) to over 200,000 hours, making these cooling pads extremely durable.

The best cooling pads offer sophisticated PWM (Pulse Width Modulation) control, allowing users to precisely balance the cooling needed for a heavy gaming session versus the near-silent operation required for a video conference.

3. Material and Design Innovation: Maximizing Heat Transfer

The physical composition of the cooling pad plays a crucial role in passive heat dissipation, acting as a large external heat sink.

Conductive Surface Materials

-

Aluminum Dominance: Aircraft-grade Anodized Aluminum remains the standard material due to its high thermal conductivity and low weight. It efficiently draws heat away from the laptop chassis through conduction.

-

Copper Integration: Premium pads integrate localized copper heat pipes or copper inserts in key areas, as copper boasts thermal conductivity nearly double that of aluminum. These copper elements rapidly absorb and transfer hot spots away from the laptop’s vulnerable components to the main aluminum body for dissipation.

Ergonomics and Airflow Geometry

The design must prioritize both cooling efficiency and user comfort.

-

Intake Vent Alignment: The most advanced designs feature movable or customizable fan modules that align perfectly with the specific intake vents of different laptop models (e.g., central or rear-vented gaming laptops).

-

Ergonomics and Stability: Multi-stage height adjustment (e.g., 6 positions) is standard. Furthermore, the highest-rated pads use anti-vibration rubber dampers and robust stands to ensure stability and reduce structure-borne noise, crucial for long work or gaming sessions.

4. Final Verdict: The Value Proposition

The Ultimate Laptop Cooling Pad 2026 is not an accessory; it is an integrated performance tool. While the initial investment for a Peltier or MagLev-equipped pad is higher than traditional models, the resulting performance gains—stabilized clock speeds, higher boost ceilings, and extended component lifespan—offer exceptional value, particularly for users pushing their systems to the limit. For corporate environments managing high-power AI and data science workstations, the reduced risk of thermal failure directly translates to lower maintenance costs and maximized asset utility.

REALUSESCORE.COM Analysis Scores

| Evaluation Metric | Score (Out of 10.0) | Note/Rationale |

| Temperature Differential ($\Delta T$) | 9.8 | Must achieve a consistent $\Delta T$ of 8°C+ under load, leveraging Peltier or sealed-chamber blower designs. |

| Acoustic Profile (Noise) | 9.5 | Must operate at sub-30 dBA at maximum speed, relying on MagLev or low-friction bearings. |

| Material Quality & Durability | 9.7 | Preference for aluminum structure with integrated copper heat sinks and 200,000h+ MTBF fans. |

| Ergonomics & Feature Integration | 9.0 | Requires adjustable height, customizable fan alignment, and integrated USB hubs/cable management. |

| REALUSESCORE.COM FINAL SCORE | 9.5 / 10 | High score driven by the critical need for advanced thermal management to unlock 2026 flagship laptop performance. |