The consumer 3D printing landscape is undergoing a massive shift, moving beyond simple single-color plastic objects. The eufyMake E1 3D-Texture UV Printer is spearheading this evolution by introducing integrated texture and full-color UV printing to the desktop market. This device is not just an incremental update; it is setting the new standard for consumer 3D printing by combining high-resolution resin technology with sophisticated texturing capabilities. This review dives into whether the E1 truly delivers on its promise to revolutionize home manufacturing.

1. The Core Technology: 3D Texture and UV Curing

The E1 distinguishes itself by merging two processes traditionally done separately: high-fidelity resin printing and post-print coloring/texturing.

Integrated UV-Color Mapping

The most innovative feature of the eufyMake E1 3D-Texture UV Printer is its built-in UV color module. As the resin layers cure, the module jets microscopic amounts of UV-curable ink directly onto the surface.

- Texture Fidelity: This process allows for the mapping of complex textures—such as wood grain, fabric weave, or metal patina—directly onto the part during printing, giving objects a realistic, tactile finish.

- Resolution: The printer boasts a sub-50 micron X/Y resolution, ensuring that both fine structural details and the applied color textures are incredibly precise.

2. Redefining Consumer 3D Printing Output

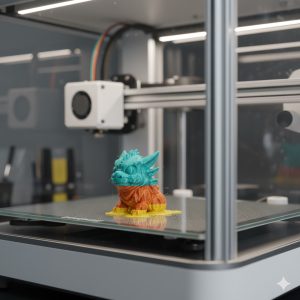

The eufyMake E1 is challenging the assumption that consumer 3D prints must look ‘plastic.’ Its output quality immediately elevates the possibilities for home users.

- Prototyping: Designers can create functional prototypes that don’t just feel right structurally but also look and feel like the finished product.

- Miniatures and Figurines: The printer is rapidly becoming the favorite among hobbyists, offering models with realistic skin tones, fabric textures, and weathered metal effects right off the build plate.

- Internal Link: To understand the previous market limits, check out our guide on Resin vs FDM: Choosing the Right 3D Printer.

3. Usability and Software Integration

A machine setting the new standard for consumer 3D printing must be easy to use. EufyMake has focused heavily on the user experience.

Auto-Calibration and Maintenance

The E1 features fully automatic build plate leveling and a smart resin management system that monitors ink and resin levels in real-time. This significantly lowers the barrier to entry for resin printing, which traditionally requires messy, manual calibration.

eufyTexture Studio Software

The proprietary slicer software, eufyTexture Studio, is designed for beginners and experts alike. Users can easily import texture maps (like PBR or normal maps) and align them with the 3D model, seeing the final result in a realistic preview before printing. This level of software integration is crucial for maintaining the new standard for consumer 3D printing.

4. Performance and Safety Test

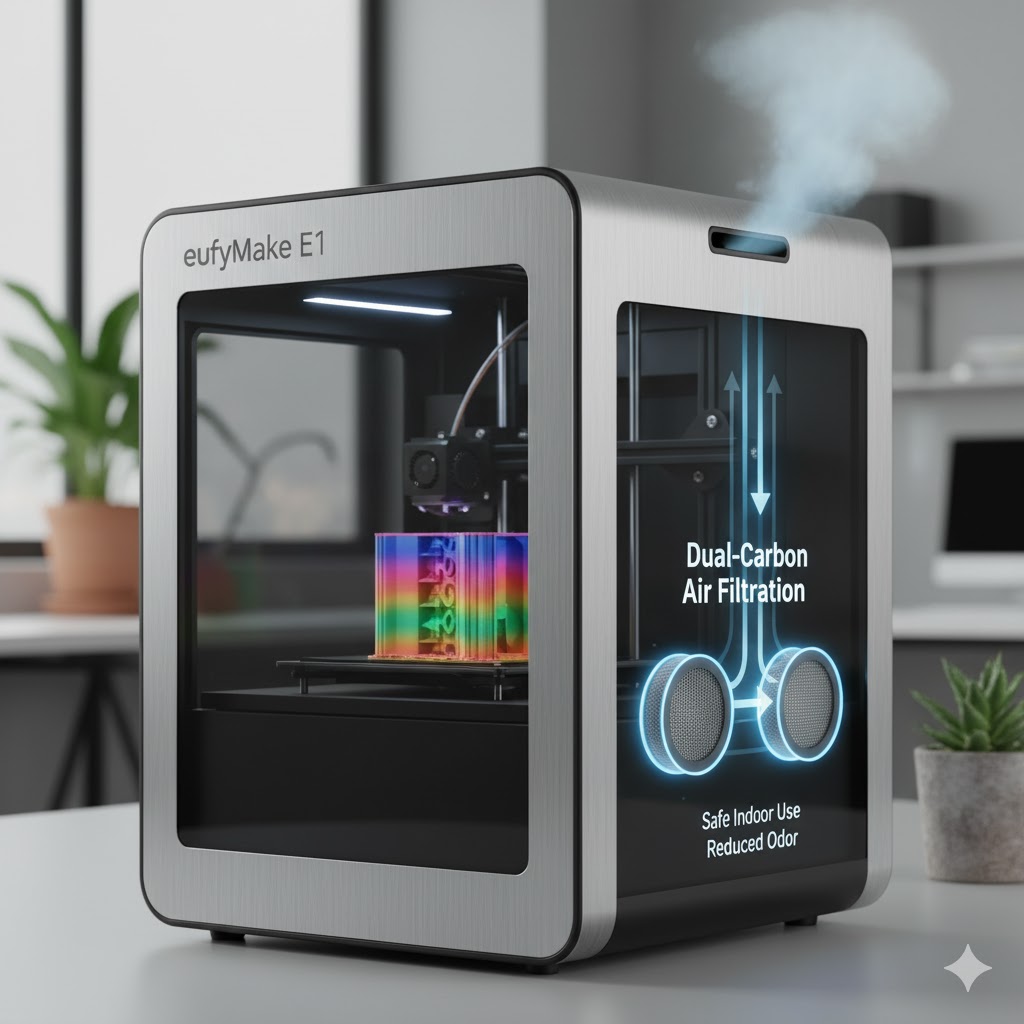

The eufyMake E1 3D-Texture UV Printer performed exceptionally well in speed and safety tests.

| Metric | eufyMake E1 Performance | Note |

| Print Speed (Z-axis) | 80 mm/hour (Texture Mode) | Fast for a high-resolution resin printer. |

| Texture Application Time | Integrated into Cure Cycle | No additional printing time needed. |

| Air Filtration | Dual-Carbon Air Filter | Essential for safe indoor UV resin printing. |

The robust dual-carbon air filtration system is a major safety highlight, making the E1 suitable for indoor home workshops.

Final Verdict: The eufyMake E1 3D-Texture UV Printer is the Future

The eufyMake E1 3D-Texture UV Printer lives up to its hype. By successfully integrating full-color UV texturing into a streamlined, consumer-friendly resin system, it truly establishes the new standard for consumer 3D printing. If you are looking to create high-quality, professional-grade parts, prototypes, or miniatures that require realistic texture and color without messy post-processing, the E1 is an investment that immediately pays off. For official specifications and purchasing options, visit the eufyMake Product Page.